Giuseppe Capanna examines the mounting fire risks of e-bikes and e-scooters and the need for better product standards and regulations.

Eco-friendly, affordable, and an efficient method to get from A to B in high-density locations, the rise in popularity of e-bikes and e-scooters will not come as a surprise to many of us. Yet, recent analysis of UK media coverage of fire incidents related to these vehicles has prompted much concern over their safety. Data collected from the London Fire Brigade (LFB) revealed a record high of e-bike and e-scooter fires across the capital in 2023 compared to 2022, with some resulting in fatalities and prompting increased safety advice for owners and users.

There are now calls for urgent attention from the likes of manufacturers, regulators, and consumers for safer practices.

Identifying risk and failure mechanisms

Electrical Safety First’s (ESF) comprehensive recent report, Battery Breakdown, provides detailed technical analysis of the causes of these battery fires. However, it also sets out 30 practical policy recommendations to government and industry to address the problem. The charity is also campaigning for better education for consumers about the very real risks associated with some types of e-bikes and e-scooters, in addition to providing its own safety advice to the UK public as ESF is keen to dispel some key misconceptions about lithium-ion battery use. They are not ‘inherently dangerous’ and lithium-ion batteries have been in wide use for over 20 years in laptops, mobile phones, and other common household electrical items and, as such, have enjoyed a long track record of safety. However, these batteries also store a huge amount of energy in a very compact format, which means that any uncontrolled release of that energy will result in a very high-temperature event.

A video released alongside the Battery Breakdown report demonstrated just how ferocious a lithium-ion battery fire can be. During a ‘nail penetration test’, ESF lab experts simulated perforation damage to a battery cell to trigger the process of thermal runaway. Caused by excessive heat, when lithium-ion cells reach 80°C or higher they can enter a condition called self-heating, where there is a natural gradual increase in temperature as a result of chemical reactions within the cell. Once those cells reach approximately 140–150°C, they can go into thermal runaway by themselves with no external heat source. When one cell goes into thermal runaway, the high temperatures produced can lead to other adjacent cells entering into self-heating and then into thermal runaway itself in a process known as propagation. In general, batteries will be engineered in such a way that they will not overheat, but this can occur if there is an additional source of heat that the designers were not expecting, such as a nearby radiator or heater. In well-produced batteries the cells inside will have a built-in safety mechanism in place.

A build up of heat can also result in the build up of internal pressure, so most cells will have a small pressure release valve or burst disc that allows the release of a plume or cloud of white vapour. Not to be mistaken for smoke, this toxic vapour is potentially explosive because it is a vaporised solvent from inside the battery. When that vapour mixes with the air and makes contact to an ignition source, some type of explosion can occur. These fires are intense and can rapidly develop, with the ability to ignite other things very quickly. An e-bike or e-scooter battery that goes into thermal runaway is akin to a box of fireworks going off in your bedroom. According to ESF’s calculations, a typical e-bike or e-scooter battery stores the same amount of energy as six hand grenades. These fires are also a different proposition from normal fires due to the chemical reaction taking place in the cells; the fire creates its own oxygen, rendering fire extinguishers or fire blankets useless. The only way to extinguish it is to submerge the battery in water or wait until all the cells have consumed their energy. Laboratory tests also highlighted that many of these battery fires can re-ignite, sending flames and sparks in all directions.

The main causes of lithium-ion battery fires to be aware of are:

- Physical damage: This is perhaps one of the most obvious failure mechanisms associated with lithium-ion batteries. High impact, external penetration, or excessive vibration can all cause an impact, and the damage results in the shortcircuiting of the battery internally, which leads to an uncontrolled release of energy. Similarly, any kind of accidental internal short circuiting of a battery will result in a high temperature, and lithium-ion batteries are particularly prone to this because they have such a high energy density.

- Overheating or overcharging: This results in a vicious cycle where the battery goes into failure because it is being overcharged or is being used too hard. Good design and good testing should prevent these occurrences from happening, but you can encounter these faults when a product has been designed cheaply or has been rushed into production.

- Manufacturing defects: In general, such defects in batteries are very rare, but this relies on them being produced by a reputable source that takes battery safety seriously.

Compared to mobile phones and laptops, the batteries found in an e-bike or e-scooter are far bigger, so when things do go wrong, the results can be far more devastating. Added to that is where these types of fires commonly occur. ESF found that many of the e-bikes and e-scooters where a fire incident had occurred had been left to charge inside residential locations, such as hallways and corridors. In many cases, these are the only emergency escape routes for residents. As half of the reported fires also occurred overnight, the risk to life and property significantly increases when the e-bike or e-scooter is left charging unattended.

Overcoming flaws in design

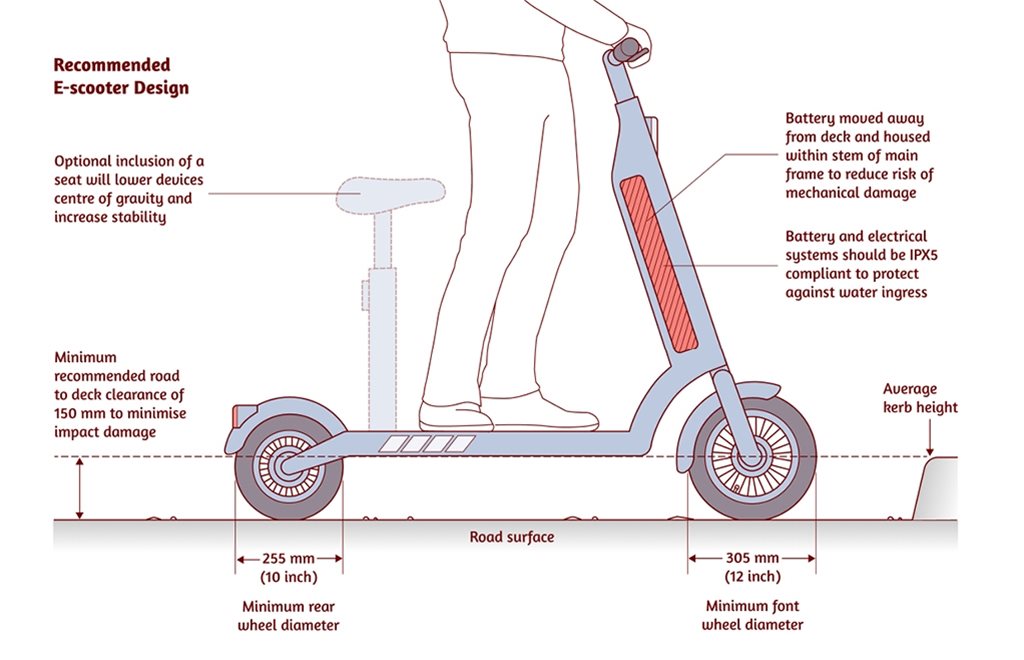

Modern-day e-scooters evolved from the popular push scooters of the 1990s, so the lithium-ion battery is mounted below the deck and the scooter itself has very small wheels. This presents a significant design flaw that results in the battery enclosure becoming easily damaged as the user encounters kerbs and potholes in the road. With punctures or damage to the enclosure, the risk of the barrier becoming broken and water ingress is greater, resulting in a thermal runaway situation. Small changes in the design could prevent such risk of impacts from the ground and water damage, such as making the wheels slightly bigger and moving the battery from under the footplate to the stem of the scooter. This will not affect the usability of the e-scooter at all, but it does improve the safety of it.

Innovations in technology have enabled manufacturers to increase the energy density of lithium-ion batteries to obtain the highest possible performance from them, and while manufacturers have mostly been successful in ensuring the right balance of safety and performance, sometimes they have got it wrong. ESF investigations found that some e-bike and e-scooter batteries can be rated up to 96 volts. Compared to EVs, which have battery systems that can go up to 400 volts, there is not only a risk of fire from the battery itself but also the risk of electric shock. Limiting the battery voltage down to 60 volts will remove the risk of electric shock. Minimum IP ratings for e-bikes and e-scooters can also make them safer for charging. Other design considerations such as a waterproof socket system should also be included so that batteries can be safely charged outdoors or in an outbuilding.

It should be noted that technologies with different chemistries do exist and are generally safer. For instance, lithium-ion phosphate is found to have a more stable type of chemistry, while lithium titanate is another very safe battery technology. However, they do not offer the same voltage per cell or the same energy density, which conflicts with the needs of manufacturers. Manufacturers want the largest energy density so that you can get much further on your e-bike or e-scooter with a smaller battery, which is why the current technology being marketed is the preferred one.

Some manufacturers, however, are coming up with additives for the lithium-ion to make it safer. There are also new technologies on the horizon, such as a lithium solid-state battery, which is half the weight of a similarly powered lithium-ion battery. This means manufacturers can retain the same level of energy density they need for manufacturing a competitive product, but the battery is far safer because it does not have the liquid electrolyte. It can also charge more quickly, reducing the risk of overcharging or it being left unattended for long periods. While we are still some years away from seeing this technology, once it does enter the market, it should make things much safer.

Removing substandard products from the market

Currently, the need for high-performing, low-cost products is dominating the UK market, with many of them being introduced from overseas. The UK offers a stringent testing process for many commonly used electrical products such as EVs and laptops. These will all be made by reputable manufacturers and have undergone a rigorous testing process. But although the UK, European, and American markets cite safety as high on their list of priorities, the same cannot be said about some types of e-bike and e-scooter manufacturers, who for the most part will opt for highest performance at the expense of vital safety measures. Many substandard products are coming in from abroad and are usually available for purchase from online marketplaces. ESF has found that a significant number of these products have not been through proper testing, which is why there are so many issues emerging. That is why we need to see mandatory third-party certification testing so that no one can put any product on the market unless it has been tested. We need to weed out those bad operators who are in the business and who are trying to cut corners as it will stop a lot of unsafe products from entering our homes.

Third-party sellers through online marketplaces are also profiting from unbranded ‘universal’ chargers for lithium-ion batteries, which can result in overcharging at higher voltages than intended. In some cases, there are chargers that are up to 96 volts that can fit a 24-volt battery because they come supplied with many different connectors. Manufacturers do this to sell more chargers, but it is not safe.

In 2022, ESF found dozens of listings of substandard e-bike and e-scooter chargers for sale through third-party sellers. These unsafe chargers were identified solely through images of non-compliant mains plugs included in the listing. The use of a non-compliant plug is a sign that the charger has not been adequately tested to the necessary safety standards and a discerning indication that further hidden dangers may exist.

During one investigation, ESF found that a particular make of e-bike had been involved in several different fires. On closer inspection, it was found that the manufacturer had declared that it met the machinery directive even though the standards it was using were the wrong standards. The instructions also did not even meet the requirements in the standards that had been claimed, highlighting cases where manufacturers are self-declaring that they have been through all of the testing, but evidence shows that they have not.

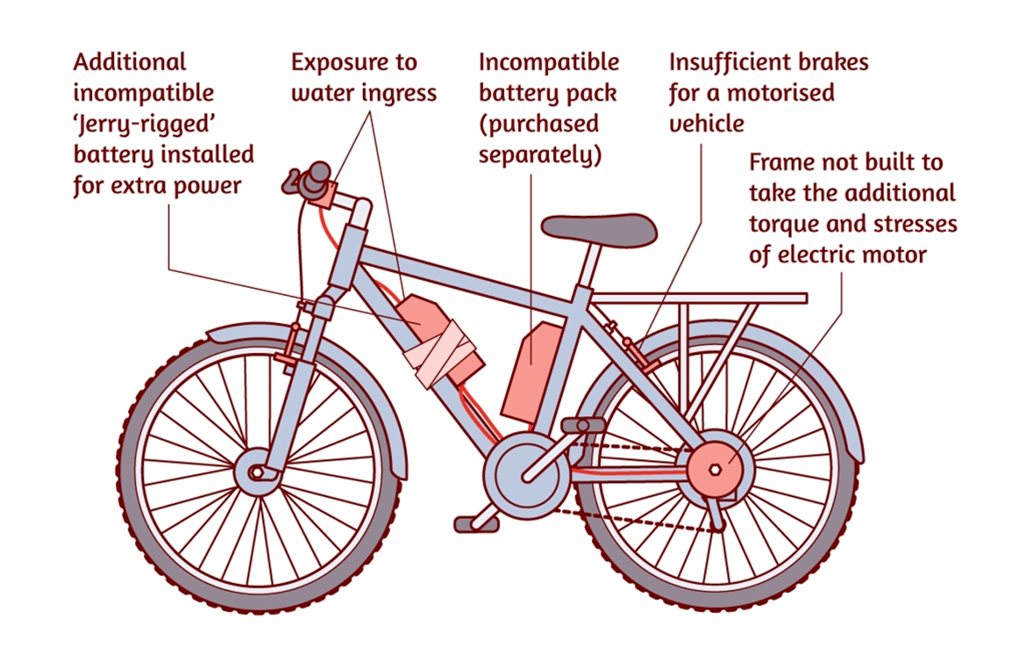

On the flip side, serious fire safety risks can also emerge when users of e-bikes and e-scooters go against manufacturers’ recommendations and carry out DIY conversions of pedal bikes and push scooters to create their electrical equivalent. The batteries in these so-called ‘conversion kits’ are widely available in online marketplaces, but often do not meet the correct safety standards. Added to this are DIY modifications to the electrical systems (to prolong battery life and/or increase speed) and other risky practices that are being promoted through online channels. There is a public perception that these practices are low risk, but the rising number of reported fire incidents tells us otherwise.

Developing new product standards

for all lithium-ion, and BS 50604, which concerns lithium-ion batteries that are specific to light EV (electric vehicle) applications.

As such, the BSI plays a vital role in ensuring that standards also keep up with evolving technology, by keeping their sights on emerging changes. However, the process of bringing out a new British Standard is a long one, particularly as it is usually derived from a worldwide standard. Another key consideration is that standards always follow technology, as it is not possible to create a standard for something that does not exist. In the meantime, it is possible to pass a Publicly Available Standard (PAS), which is quicker to create and plays a key role in ensuring that proper information and guidance related to electrical goods are out there for users to follow. In the same vein, technical specifications for e-bikes and e-scooters can also be produced that go a lot further than the standard. These guidance documents can get out into the market much quicker than product standards, and once they have been created, the BSI committees will look to use those documents to make their standards, improve other standards, and hopefully make products safer.

We hope that these standards will continue to evolve to improve safety for users, but in the meantime, it is up to the manufacturers to ensure their products have been tested to the proper standards and ensure they comply with legislation. While that is the first step, we encourage manufacturers to not rely on those standards for their products but to consider all the risks associated with a product. When you test a product according to its standard, it can only cover the risks that are in that product standard, but if you do your own research and development, you may find other risks. Carrying out a risk assessment will also cover those other hazards that might not be covered by the standard.

User instructions should also be detailed and kept up to date, with enough information for users to know how to use a product and understand that they must only follow the manufacturer’s recommendations. A current misconception for consumers is that if a charger fits, then it must be correct, but that is not the case with e-bikes and e-scooters. We urge consumers to make sure they only use the charger that came with the e-bike or e-scooter and get a replacement from the manufacturer until the standard has evolved to remove that risk.

Calling for better regulation

ESF believe that batteries for e-bikes and e-scooters should be regulated like fireworks and heavy machinery to better ensure their safety as, currently, manufacturers can simply self-declare their devices as being safe. This would not be an unprecedented move – it is already in place in New York City, where new rules came into effect in September 2023. These require e-bikes, e-scooters, and their batteries to be certified as safe by a third-party organisation before coming onto the market.

Closer to home, ESF is working with Yvonne Fovargue, MP for Makerfield in Greater Manchester, to introduce a parliamentary bill seeking to make provisions regarding the safety of e-bikes and e-scooters and the batteries that power them, including the safe disposal of secondary lithium batteries. This bill has the backing of the FPA and other leading fire safety organisations. Other measures include the introduction of a British Standard for conversion kits for e-bikes and measures to ensure safer charging practices.

In December 2023, the Office for Product Safety and Standards (OPSS) issued a government-backed safety message warning customers only to purchase products that had been sufficiently tested to the correct standards. Soon after, in January 2024, the OPSS took enforcement action against a dangerous e-bike battery that had been manufactured by a China-based manufacturer. Withdrawal notices were issued to online marketplaces supplying UPP batteries and customers were advised against using them.

There has been some progress, but time is of the essence. The UK government needs to take urgent action to improve e-bike and e-scooter safety. There is no silver bullet to tackle e-bike fires, but implementing our recommendations would protect good manufacturers, weed out bad ones and, most importantly, save lives.

Safety tips for users of e-bikes and e-scooters

When buying a new e-bike or e-scooter, make sure you buy it from a reputable manufacturer. That is the best way you can make sure that your e-bike or e-scooter has been through the proper safety testing and that it is safe.

Only use the charger that came with the e-bike or e-scooter. If you need to replace the charger because it has been damaged or broken, go back to the original manufacturer and get a replacement from them. That way you can make sure that the charger is compatible with the battery.

Avoid charging the e-bike or e-scooter in escape routes where it is going to stop you from getting out of the building.

Once it has finished charging, unplug it. Don’t leave it on charge for days on end because that increases the level of risk. If you can, don’t charge it overnight. If you do need to charge overnight, just make sure you have working smoke alarms so that if something goes wrong, it’ll give you that extra warning that will help you get out of the building.

Do not try to tackle a fire on your own. If something does go wrong, and you do see smoke or fire coming from your e-bike or e-scooter, just get out of the building and call the fire services because that might save your life.

Graphic illustrations provided by Electrical Safety First.

ESF’s ‘Battery Breakdown’ report is available to download here.

This article included data and research on thermal runaway taken from ‘A Review of Lithium-Ion Battery Thermal Runaway Modeling and Diagnosis Approaches’, Processes 2022, 10(6), 1192;

https://doi.org/10.3390/pr10061192

View ESF’s curated video playlist on e-bike and e-scooter safety here.

Fire & Risk Management is the UK’s market leading fire safety journal, published 10 times a year, and is available exclusively to FPA members in digital and print format depending on your requirements. You can find out more about our membership scheme here.

Giuseppe Capanna is a Product Safety Engineer at Electrical Safety First.