Key steps towards a high quality sprinkler system installation and better fire protection are explained here by Graeme Leonard

HAS FIRE protection ever been so pivotal? Buildings continue to grow both in height and volume; storage has increased in density; and the commodities being stored may require different levels of protection from those we have seen in the past. Essentially, the contents of buildings, be they people or objects, are becoming harder to protect, and the commodities stored more valuable.

This is why it is so vitally important that companies work with qualified fire protection specialists to make sure their systems are designed, installed and maintained to the relevant standards. Fire protection systems are a life saving, but often invisible, part of any construction project. Though specific guidelines and standards may vary, the European fire protection industry is united in believing that buildings must have properly installed fire protection systems which will protect people, equipment and the actual building from harm, should a fire start.

The sector is currently in the process of reexamining the application of fire protection systems in buildings with high occupancy, such as schools, care homes and high rise buildings. Fire safety professionals find themselves having to reevaluate traditional methods due in part to a need for the industry to modernise, but primarily because of a number of challenges they increasingly face.

Projects are impacted for contractors, as they simultaneously come under pressure to achieve high standards whilst being restricted by limited budgets, tight deadlines, and the uncertainties around availability and quality of labour. The industry’s answer will most likely be to focus on high quality products that allow for speed and ease of installation without compromising on cost and reliability.

Certainty in installation

Installations which do not comply with locally applicable codes and standards represent a key challenge for the fire protection industry. If products are installed incorrectly, they not only run the risk of systems not providing adequate protection in case of fire, but they can also exacerbate the threat of danger.

For instance, problems can arise from sprinklers being installed too close to the ceiling or being incorrectly spaced, which can affect how comprehensively an area is covered. If the wrong sprinkler is used for a specific risk – unfortunately not uncommon in fire protection systems – it can lead to a misaligned system, which may not function as required in case of an emergency.

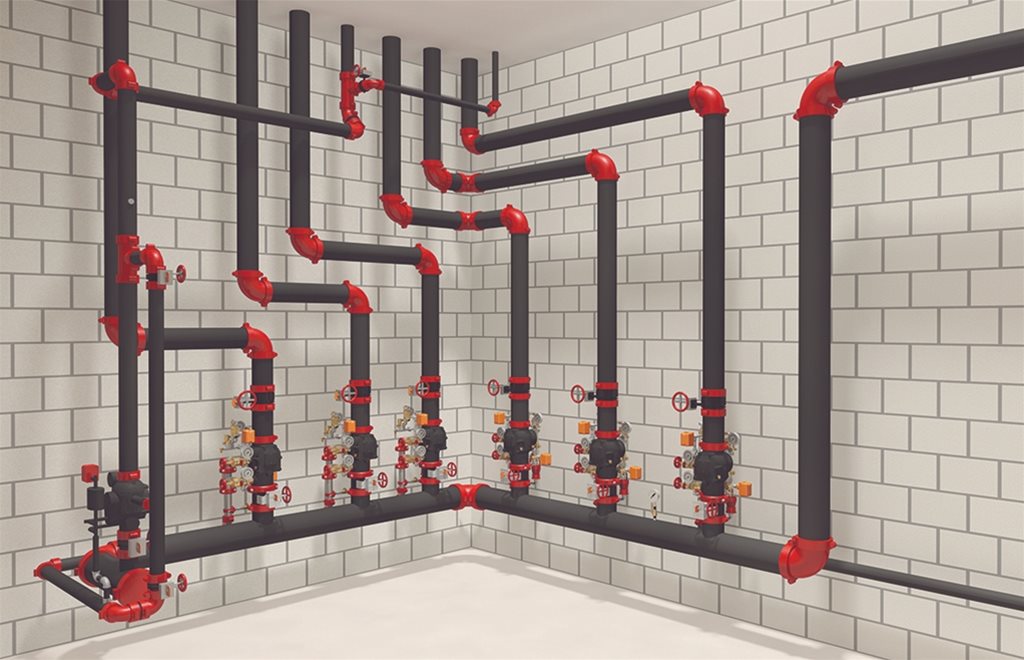

Using products specifically designed for quick and easy installation helps to avoid such issues. The features deliberately assigned to the V9 suite of storage sprinklers from Victaulic, for example, do just that, giving contractors confidence in the knowledge that systems will be installed correctly first time.

Indeed, an ‘Installation-Ready’ sprinkler is part of the V9 suite. The design of this sprinkler’s coupling was specifically created so that it could be installed with improved speed and certainty of correct installation versus a threaded sprinkler, while also avoiding mess and consumables such as thread sealant and PTFE (Polytetrafluoroethylene) tape. This in turn enables contractors to better control their labour and optimise the number of workers on the ground.

Training for resilience

In order to ensure certainty in installation, it is essential that those involved in design, installation and maintenance are fully trained in the products they are working with. Some jurisdictions require that a contractor states the product use, as well as being able to demonstrate that relevant training has been received. However, this practice is far from being universal.

Many manufacturers of approved products used in Europe will gladly offer ‘hands on’ training to their customers in the appropriate use of their products to aid efficient and safe installation. It would be a significant step forward for authorities having jurisdiction to make this a requirement for all approved products, both as a means of improving safety and also cost and time efficient installations.

There is a consensus that the construction industry is going through a period of change. To stay competitive and provide clients with better service, we must openly embrace the integration of new techniques, technology and equipment into our repertoire. But to realise the full potential of these modern approaches – including new products brought to the fire protection market in the last five to ten years – they must be paired with the education of and hands on training for the workforce; not only those in manufacturing organisations, but also on the job sites up and down the country.

Contractors are realising the project efficiency and security gains of a well trained and skilled workforce, and they need partners to work alongside them that understand their needs at every stage of the project life cycle. Manufacturers have a role to play in the upskilling of the construction workforce and should be partnering with contractors, owners and engineers to drive training programmes to that end. Yet, despite these clear benefits, many suppliers do not involve themselves in the training of the contractors and engineers who use their products.

As new technology continues to develop and the way we provide fire protection systems continues to adapt, the importance for workers, contractors and customers of preparing and equipping the construction workforce with the relevant, up to date skills has never been more real. Importantly also, this will equip the industry with the necessary resilience and opportunity to thrive in the future.

Innovation reduces risk

Contractors have been faced by the age old challenge that has revolved around how quickly a project can be completed to the highest standard and at a reasonable cost. The contractor will start to address this challenge by speedily going to its supply partners to produce the best framework for the project. Backed by its team of specialists, the contractor will then go back to the client with a solution which hopefully fits the bill.

In the context of fire protection projects, contractors are on the lookout for new products that will increase efficiency whilst maintaining high quality. While traditional methods, such as threaded sprinklers, have worked in systems for more than 100 years, occasional leaks cannot be avoided and often result in additional man hours and costs being incurred to resolve the issue.

Recently, new alternatives have come on the scene, incorporating innovative product design to raise the bar for reliability and speed of installation. These include new products that have been able to eliminate oil drippings and shavings typically produced during the threading process.

Furthermore, modern methods have looked to improve the problem of pipe thickness being reduced due to corrosion at the point of threading, while also enabling contractors to use lighter, smaller piping in the first place. That in turn results in an installation that provides consistent quality over the life of the system at a potentially reduced cost.

One answer is our Firelock IGS line, which enables contractors to use mechanical pipe joining on 25mm pipe, avoiding the need for threading and the mess and risk of pipe corrosion that comes with it. Clients’ questions about reliability are also answered by incorporating visual confirmation of pad to pad installation to ensure leak free joints.

Unexpected costs

Inherently linked to system installation is the way that contractors are often subjected to costing and cash flow fears throughout a project. It is important to advocate for products which are simple enough to use and also encourage the application of prefabrication and modularity.

Well established in the heating, ventilation and air conditioning (HVAC) sectors, software enabled by building information modelling (BIM) has recently experienced rapid growth in popularity in the fire protection sector across Europe, particularly in the UK, Netherlands and Scandinavian countries. BIM enabled software, such as Revizto, allows models of fire protection systems to be visualised, shared and amended in real time.

By introducing this technology into the pre site process, contractors and engineers can be confident that the materials which arrive on site meet their requirements and avoid potential surprises that result in increased man hours and impact the total cost of installation.

In addition, the application of BIM enabled products allows potential system threats to be simulated and mitigated earlier on in the project. Not only does this change in behaviour promote an efficient approach to developing projects, particularly in the fire protection sector, but it also permits budget costings to be considered at an earlier stage in the process.

In addition, contractors have confidence that the materials are prepared to correct specifications and thus are ready to be installed, without the need for amendments down the line. As time has already been taken to pre plan and prefabricate the system, the project can therefore save labour costs normally present at installation.

Quality delivery

It is not easy getting fire safety right, but we all know why it is so important that it is delivered to a high standard. New products providing reliability, ease of installation and ultimately confidence to clients alongside pre worksite preparation come together to provide an industry landscape in which contractors can take the project from start to finish with the assurance that they are doing things in the correct way

Graeme Leonard is director of sales for fire protection at Victaulic